Hepworth Brewery is ramping up its sustainability drive by becoming the first business in the UK to trial a new heat pump which can cut carbon emissions by up to 90%.

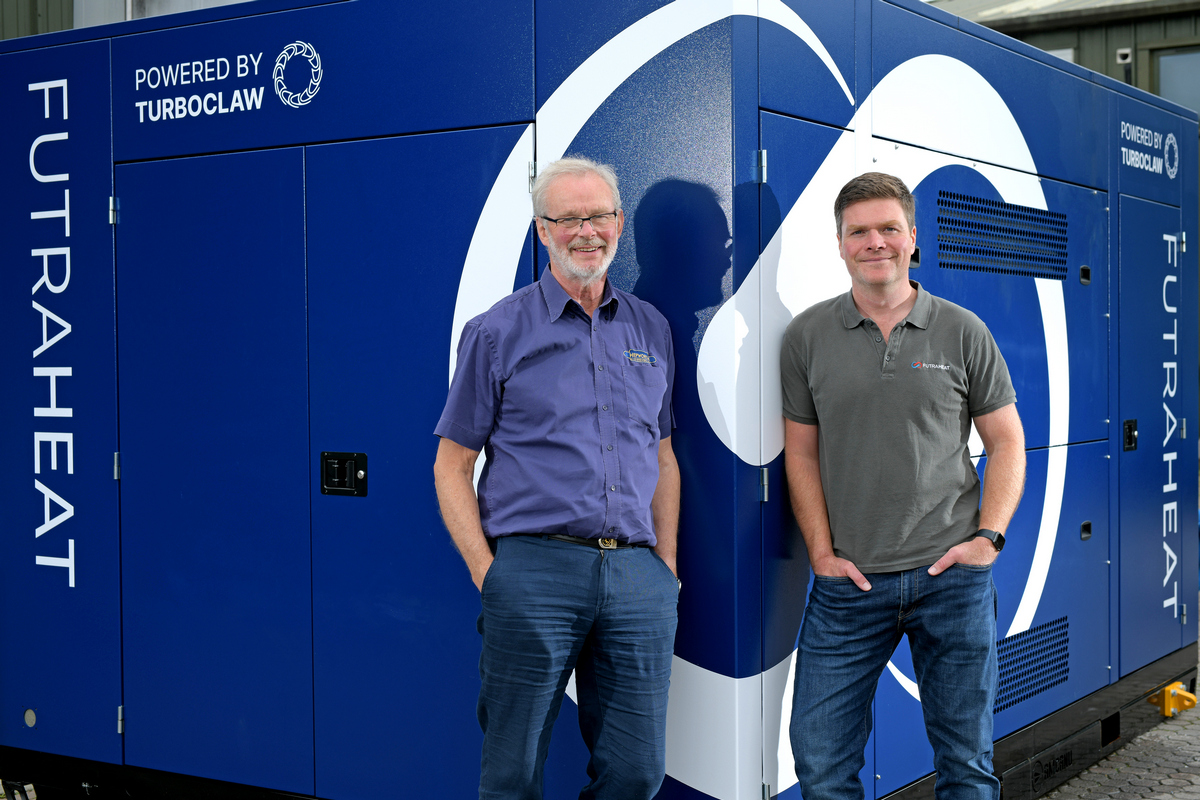

Hepworth Brewery chairman Andy Hepworth with Futraheat chief executive Tom Taylor

The Greensteam heat pump from Futraheat cost-effectively recovers low-grade waste vapour from the brewing process and delivers it back as steam with a temperature of 130oC. This is far higher than most heat pumps, which typically deliver hot water up to around 80oC. This is the first time a steam-generating heat pump has been installed in the UK.

Initially operating on just the boil stage of brewing at Hepworth Brewery, the heat pump could, if rolled out across the business, replace the oil boiler completely, enabling the brewer to cut carbon emissions by up to 90% and reduce fuel costs by around 40%.

The new heat pump is the latest in a long line of sustainability measures undertaken by the brewery, which is on track to fulfill its ambition of becoming 85% carbon neutral by the end of 2025.

Later this year, it is installing an industriWASE anaerobic digester, which converts the organic matter in wastewater into biomethane, a renewable energy source. It expects to eventually treat 7,800 cubic metres of wastewater a year and save more than 100 tonnes of CO2 emissions.

“Sustainability has driven the way we do business from Day 1 and the heat pump, if successful in trial, will be an important next step on our journey to carbon neutrality,” said brewery chairman Andy Hepworth.

“With heat such a vital part of the brewing process, finding a solution that delivers the heat we need, while also cutting our emissions and costs, promises to be transformational.

“Futraheat and WASE are both pioneers in sustainable technology, and we are delighted to be partnering with them to realise our shared ambitions for a cleaner, lower-carbon future.”

Other sustainability initiatives at Hepworth Brewery include installing solar panels; using reed beds to clean its low-grade effluent; taking heat from beer chillers to heat the brewery offices, shop, and taproom; and installing rain recovery equipment, with the water used for cleaning. The brewer also strives to minimise its food miles by sourcing barley and hops as locally as possible.

At the same time, Hepworth Brewery is introducing a new logo and strapline of ‘great beer, naturally’ to encapsulate its ethos of brewing great-tasting beer from natural, high-quality ingredients, while continually striving to become a more sustainable brewer.

Andy added: “All brands evolve over time, and it became clear that we needed a new strapline. ‘Great beer, naturally’ really gets to the core of what Hepworth Brewery is all about and will help us to communicate more effectively to all our audiences.”