British brewers could cut their carbon footprint using a new type of electric storage boiler developed by British start-up Caldera.

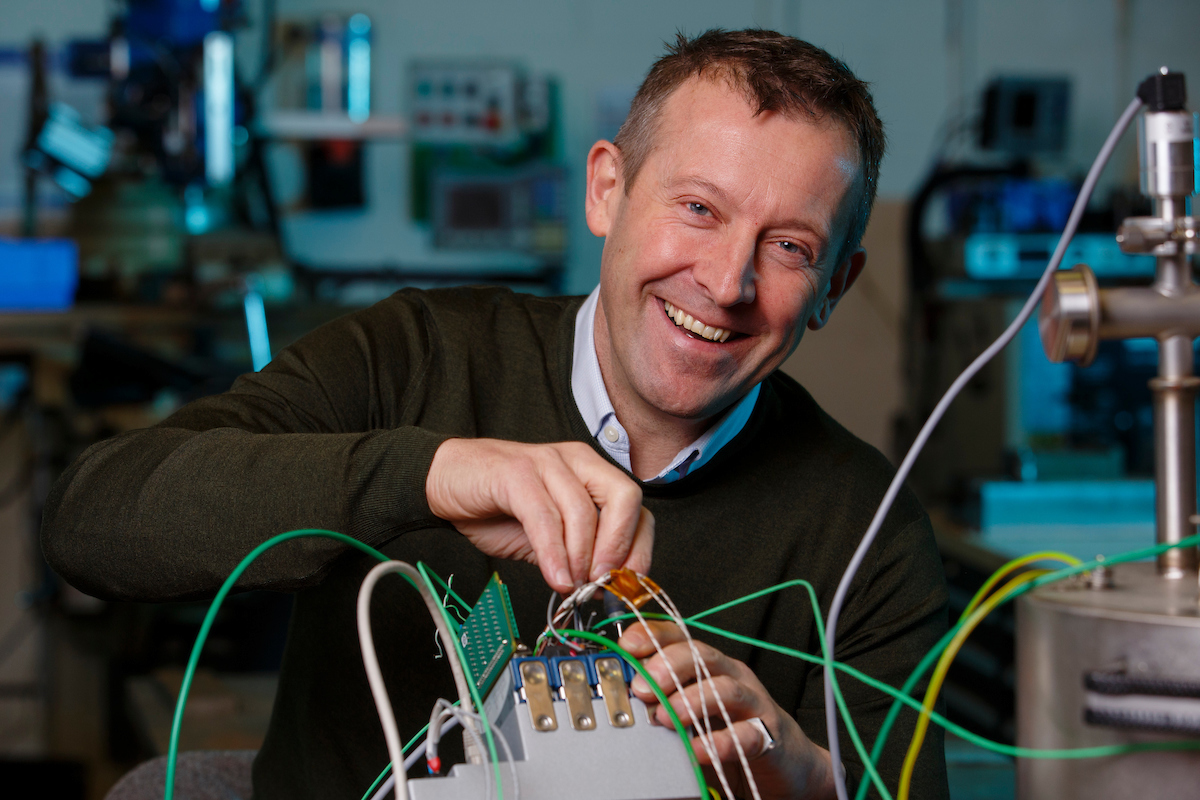

James Macnaghten, CEO of Caldera, at the factory in Fareham, Hampshire. Photograph : Luke MacGregor

The patented technology can generate process heat or steam for brewing without the use of carbon-emitting gas or oil.

Caldera storage boilers use a solid material which is heated up using surplus energy from wind farms and on-site renewables such as solar PV. This energy is then stored with very high efficiency and released when required as high-pressure steam.

The Southampton firm is already producing a domestic-scale heat store, which is currently being rolled out in a number of trial homes countrywide.

It is now seeking to scale up their product for industry. It has secured a £295,000 grant from the Department of Business, Energy, and Industrial Strategy (BEIS) to investigate the design and build of a UK factory capable of rolling out the boilers at scale.

Caldera chief executive, James Macnaghten, said: “Industrial steam makes up 31% of the UK’s total industrial heat requirement and is a major element of the brewing process. This is normally provided by multiple steam boilers and accumulators that burn gas or oil.

“Banks of solid-state electric storage boilers can be charged up by off-peak renewables and on-site solar PV and can hold this heat for hours, ready to deliver high pressure steam as required at temperatures up to 200ºC. This will enable brewers to switch off fossil fuels as their primary fuel source, enabling an easily adopted route to low-carbon electrical power.”

He added: “In addition, industrial steam boilers and steam accumulators store large quantities of superheated water, which brings significant cost and safety implications, requiring continuous manning and detailed annual inspection. The adoption of electric storage boilers avoids these risks due to the low quantity of water used without combustion.

“Our product offers industry low-carbon heat with a system which is simple, safe and easy to integrate.”